NorthClad® ACM Series Installation Notes:

Product Description and Intended Application

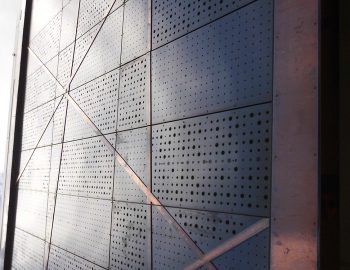

ACM Wall NorthClad® ACM (aluminum composite material) Series panels are designed for use as an external wall cladding in conjunction with a proper weather resistant barrier to form a back-ventilated, rainscreen design. The cladding creates a protective layer for the building’s waterproofing membrane(s) by providing a durable and aesthetically pleasing surface. While the panels will significantly discourage the entry of surface water, some water will enter the drained and ventilated cavity behind the panels and must be repelled by the weather resistant barrier.

The contractor, designers, and installers must be clear on the location of the building envelope drainage plane. The drainage plane exists behind the NorthClad® ACM system where the weather resistant barrier (WRB) is applied to the sheathing, not at the face of the panels (or in the panel reveals).

External Wall Cladding

The NorthClad® ACM system is designed to transfer wind loads to the supporting structure. The panels and their respective sub-framing are not designed to contribute to the structural stability of the building.

Due to free-flowing air in the cavity behind the panels, the NorthClad® ACM panel system requires a complete weather resistant barrier on any wall which it is installed. The integrity of the WRB design can be verified by water testing the walls after the WRB is installed and prior to the application of the rainscreen panel system. In the area where panels are being installed, the building envelope should be completely weather tight prior to the installation of the NorthClad® ACM system.

The envelope does not rely on the face panel (NorthClad® ACM) for watertightness. Please see Appendix A for additional information on weather resistant barriers.

Fire Resistance

NorthClad® ACM fire resistance ratings vary depending on the type of composite material selected. It is important to determine the proper class of material required for your project.

The design should consider any combustible material behind the cladding which may be exposed in a fire. It is the responsibility of the project designer to determine the combustibility of materials behind the cladding system and implement cavity barriers or other measures as required under relevant building regulations. Additional measures for ventilation may be required if a cavity barrier is created behind the NorthClad® ACM system. Please contact your NorthClad® representative for further information.

The NorthClad® ACM series rainscreen system does not typically contribute to the fire resistance of any external wall or load bearing structure, though ACM material with a fire-rated core is also available.

Design of the Cladding System

Prior to installing the NorthClad® ACM system, verify the building is properly protected with a weather resistant barrier (WRB). Special attention should be taken at areas where the WRB is interrupted. Penetrations (interruptions) include but are not limited to: flashings, windows, doors, scuppers, electrical boxes, pipe penetrations, etc. Please see Appendix A for additional information regarding weather resistant barriers.

Ventilation spaces should allow for uninhibited vertical airflow. The design of the NorthClad® ACM rainscreen system allows it to be fastened directly to the wall framing or furring strips. Achieving a ventilation compartment is accomplished by spacing the system from the wall. Without this essential spacing, the system will not breathe correctly and will likely trap water, condensation, or other moisture. For proper ventilation, the system must be installed with offset clips at every fastening point, which, aside from providing this essential ventilation, will allow for minor adjustments to compensate for slight inconsistencies in the substrate; keeping the panel faces on the same plane.

Delivery, Site Handling and Storage

Upon arrival of your order, inventory and inspect each panel and all accessories, and note any damage to panels, packaging, or accessories. If there are any signs of damage, note the bill of lading at the time of delivery. Failure to do so can make it difficult to file a freight claim. Send a list of damaged materials to NorthClad® and contact your NorthClad® representative for further instructions. It is crucial that damaged panels, accessories, or packaging be reported to NorthClad® as soon as they are discovered.

ACM Series panels should be transported using NorthClad® standard pallets. Bailing bands are to be removed upon delivery. Lift the panels from each stack individually, taking care not to scratch or damage any adjacent panels when removing panels from the stack.

Panels can be stored vertically on a flat surface free of debris, or kept on pallets with supports at 12 inches on center or less. All horizontal surfaces, including panels and pallets, should be covered with a clean membrane or board to protect the panels from damage. Unwrapped stacks should be covered with plastic sheeting in order to minimize damage from dirt and moisture. Remember to remove bailing bands prior to storage.

Panels need to be stored in an area that is well covered from the elements, cool, ventilated, and dry.

Preparing Panels for Use

Pay close attention to the direction of the material during installation and field fabrication. The majority of ACM material is directional; that is, during manufacturing the paint is applied to the composite material in one consistent direction. In order to maintain color and finish consistency across panels, each panel’s material must course in the same direction. Most ACM materials have arrows on the protective film that show which direction the finish was applied. NorthClad® takes this into consideration during panel fabrication and notes should be made on the drawings to verify the direction in which to install the panels. Remember, all panels need to be installed in the same direction throughout a project unless intentionally noted otherwise.

To avoid scratching the panel finish, all cutting, routing, and drilling should be performed from the backside of the ACM material. ACM consists of two layers of .020 aluminum sandwiching a polyethylene (PE) core, or in some cases a fire-rated (FR) core. Both materials are fairly easy to cut and route.

For straight cutting: use a circular saw with a fine-carbide tooth blade. For arches, holes, fine precision cuts, and other detailed areas: use a jig saw with a fine-tooth metal blade. For routing: use a standard router with a 110 Degree “V” type router bit or a 3/8 inch “Core-Box” type bit. For drilling: use a standard metal drill bit.

Inspecting the Building

The building substrate must be plumb and square. A panel system installed out of plumb will result in inconsistent grid lines, as well as improper alignment at windows, doors, corners, and other transitional areas. Panels installed on an inconsistent substrate will most likely need to be re-installed. Please make sure to verify the condition of the substrate to receive the panels before proceeding.

Installing the panels

Vertical Conditions Start by running plumb lines or a laser at all panel transitions. This is done to determine the proper distance for shims before installing the panel system. Also locate a base control line (starting elevation and angle benchmark) to help keep the panel system square & level.

Horizontal Conditions

Install the first panel in a critical transition area like a corner. Proper mounting of the first panel helps with the alignment of adjacent panels. Install the panel at the lowest point to meet your control line with the backside of the system slightly proud of the plumb line. This will establish a critical, and accurate, starting point. It is essential to the installation process that the first panel be positioned correctly, and installed square and plumb.

Alignment & Consistency

After the first panel is installed, continue with adjacent panels in the same manner along the control line(s). Verify the panels’ spacing often. NorthClad® recommends using the proper sized shims between panel faces to ensure accurate spacing. between panels. If panels are installed with incorrect spacing, they will likely need to be re-adjusted to align properly.

Seam Splines

When installing splines in the seams, run the longer splines vertically and the shorter splines horizontally. This makes replacing a panel less difficult if one becomes damaged in the future.

Panel Clips

When installing the panel clips, verify they are in line with the building’s stud framing or furring. The clips attach to the building’s framing and clip spacing may vary depending on your project’s engineering requirements. NorthClad® recommends doing a panel mock up by marking the film on the edge of the panel at locations coinciding with building framing members, then attaching the panel clips to the panel extrusion at these markings. Once the panel clips are attached, the panel is ready to install. Leave the protective film in place until the adjacent panels are installed, however, note that exposure to sunlight is not recommended as the protective film may cause color variation.

Fastening

Fasten the clip firmly to the wall, tightening the fasteners no more than a half turn beyond snug. Be careful not to over-torque the fasteners, as this may result in the fastener shearing and can strip the framing. Always make sure fastener size and spacing is in accordance with the engineering requirements for the specific project.

Panel Sequencing

Due to the nature of most panel systems, certain panels are installed prior to others; This is particularly true around doors, windows, penetrations, and other openings. Develop a written plan or sketch that takes panel installation sequence into consideration, and periodically evaluate the panel placement plan to avoid unforeseen circumstances.

Panel Protective Film

It is important to remove the protective film for each section of adjacent panels immediately after the installation is complete for that section. Extra attention is required in areas receiving a large amount of sunlight. Too much exposure, may cause panel color variation. In addition, removing the film regularly allows for further inspection of the panels condition before moving to the next section.